I ran the .38 Special revolvers through the wringer a few weeks ago, working up and testing some performance handloads. The tests concentrated on four different loads, all using 158 grain lead SWC bullets. As always, the same four revolvers were used, 2 of which have been used for many years for all .38 Special chronograph testing.

![Image]()

Smith & Wesson Model 10 2-inch

![Image]()

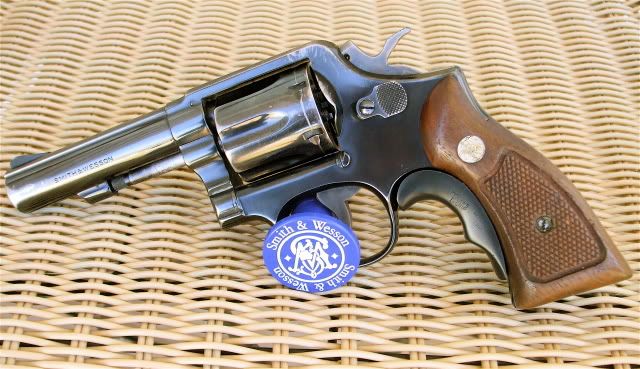

Smith & Wesson Model 10 Heavy Barrel 4-inch

![Image]()

Smith & Wesson Model 27 .357 Magnum 6-inch (since no 6-inch Smith & Wesson 38 Special revolver was on hand)

![Image]()

Smith & Wesson Model 14 8 3/8-inch

The other tests from this .38 Special epic may be accessed here:

http://www.defensivecarry.com/forum...orum/defensive-ammunition-ballistics/107972-some-38-special-velocity-tests.html

http://www.defensivecarry.com/forum/reloading/118121-three-38-special-handloads.html

The bullets tested a couple of weeks ago were from a batch I cast perhaps 20-25 years ago using the Lyman No. 358156 mould. They actually weighed 159-160 grains. They were well-formed with nice sharp shoulders and bases. They were made from straight wheel weights with some range lead thrown in as I recall (not very scientific I'll admit). They were lubed with stick Alox. I was a bit concerned that the lube would be dried out but the bullets didn't seem to lead too badly despite being abused with heavy handloads. At the conclusion of the tests the revolvers scrubbed up easily with no sterner measures required to "get the lead out."

Loads tested

The loads tested were published loads from "back in the day." Loading manuals are more mild mannered these days.

5.4 grains of Unique

This was published as maximum by Lyman for many years. A friend has nicknamed it the "Texas FBI Load" and it does make a good substitute for the factory +P 158 grain lead SWC load. The latest formulation of Unique was used for the tests. Unique seems to be "jazzed up" a bit from that used in tests 30 years ago. I first noticed this when testing Unique earlier this year. (1980 velocity tests using 5.4 grains of Unique with the lead 158 grain bullet: 2-inch-847 fps, 4-inch-935 fps, 6-inch 1021 fps, 8 3/8-inch 1007 fps).

5.0 grains of Herco

This was prepared on a whim, just to see what it could do. 5.0 grains seems to be around maximum in most data sources though the infamous Speer No. 8 shows a maximum of 6.5 grains of Herco. It was decided not to take Herco that high.

11.5 grains of 2400

This also was a published maximum by Lyman for many years. Some folks considered this to be a .38-44 equivalent handload for the .38 Special. The latest formulation of 2400 was used. I'd tested this load many years ago but the data didn't get recorded for some reason so a retest was needed. I was curious about the performance level of 2400 with the 158 grain lead SWC in the .38 Special.

8.0 grains of SR 4756

"The Load" It's bigger! it's better! It'll give all the performance one can squeeze out of the .38 Special. This is the starting load for this powder as published in the Speer No. 8 guide. I'd hate to try to work this one up to the maximum listed charge weight which is only one grain higher. Whether it is advisable to use even the listed starting load is subject to debate. Probably not. The Speer No. 8 was compiled in the late 1960s. Maybe they were smoking "cigarettes and all kinds of things" while working up loads in their lab back then.

Since we'd already tested 5.1 grains of Unique earlier this year we didn't bother to work up to maximum with it. With the other loads the effort was made to work from arbitrary lower levels in .2 grain increments toward the goal charge weights. Herco was worked up from 4.6 grains. 2400 was worked up from 10.5 grains and SR 4756 was worked up from 7.5 grains.

Working up the three loads in three different .38 Special revolvers was a bit tedious and, frankly I'm not certain that much may be determined by doing this in the .38 Special given its normal operating pressure levels. I wonder if any of the assumed pressure "signs" can be reached until one is operating fully within .357 Magnum territory which is far beyond .38 Special levels. Only the SR 4756 load showed a dab of cratering and that was in my old favorite 4-inch Model 10. Cases for all 4 loads gave normal ejection in all revolvers. Of course both "The Load" and the max. 2400 load could be straying closer to .357 Magnum pressure levels.

Some limited range time was spent shooting these loads at paper to see what sort of accuracy may be expected of them. I'm thinking that the .38 Special revolvers were grateful to see the backside of these tests.

158 Grain Lead SWC/5.4 Grains of Unique

2-inch Barrel

MV 964 fps

ME 326 ft./lbs

ES 75 fps

SD 33 fps

4-inch Barrel

MV 1026 fps

ME 369 ft/lbs.

ES 31 fps

SD 13.4 fps

6-inch Barrel

MV 1047 fps

ME 385 ft./lbs.

ES 43 fps

SD 16.6 fps

8 3/8-inch Barrel

MV 1149 fps

ME 463 ft./lbs.

ES 56 fps

SD 23.3 fps

158 Grain Lead SWC/5.0 Grains Herco

2-inch Barrel

MV 912 fps

ME 292 ft./lbs.

ES 38 fps

SD 14.3 fps

4-inch Barrel

MV 964 fps

ME 326 ft./lbs.

ES 34 fps

SD 14.5 fps

6-inch Barrel

MV 976 fps

ME 334 ft./lbs.

ES 64 fps

SD 23.7 fps

8 3/8-inch Barrel

MV 1069 fps

ME 401 ft./lbs.

ES 83 fps

SD 33.1 fps

158 Grain Lead SWC/11.5 Grains 2400

2-inch Barrel

MV 1037 fps

ME 377 ft./lbs.

ES 71 fps

SD 30.2 fps

4-inch Barrel

MV 1150 fps

ME 464 ft./lbs.

ES 50 fps

SD 26.8

6-inch Barrel

MV 1162 fps

ME 474 ft./lbs.

ES 58 fps

SD 22.2 fps

8 3/8-inch Barrel

MV 1102 fps

ME 426 ft./lbs.

ES 67 fps

SD 24.0 fps

158 Grain Lead SWC/8.0 Grains SR 4756

2-inch Barrel

MV 1150 fps

ME 464 ft./lbs.

ES 51 fps

SD 26.5 fps

4-inch Barrel

MV 1234 fps

ME 534 ft./lbs.

ES 23 fps

SD 12.3

6-inch Barrel

MV 1251 fps

ME 549 ft./lbs.

ES 23 fps

SD 8.9 fps

8 3/8-inch Barrel

MV 1173 fps

ME 483 ft./lbs.

ES 18 fps

SD 7.7 fps

It will be noted that the slower powders still register the highest velocities in the short barrel.

During this test it was surprising to find that both 2400 and SR 4756 gave higher velocities when fired out of the 4-inch and the 6-inch barrels rather than when fired out of the 8 3/8-inch barrel. This has never occurred before and I can't explain it.

It appears that the 2400 load can duplicate the performance of the Buffalo Bore +P 158 grain lead SWC factory load and that "The Load" can whip the Buffalo Bore factory load except in the 8 3/8-inch barrel of the Model 14. Buffalo Bore was the velocity champion in that barrel with the 158 grain bullet weight, strange as it may seem.

How stressful these handloads are compared to the Buffalo Bore load is hard to say. All are probably high pressure with "The Load" likely winning the prize. No primers pierced or flowed and a hint of cratering was only observed on a few, but not all of the primers in the Model 10 Heavy Barrel when used with "The Load." All cases dribbled out of cylinders when started with the ejector rod.

Recoil was brisk but very manageable in the two Model 10s. In the Model 27 and the long-barreled Model 14 recoil doesn't amount to much. All gave a snappy report and "The Load" seemed to give a particularly evil crack. Perhaps it's all in my head though.

"The Load" damaged one my spinning quail discs. I was using the top of a disc for an aiming reference for chronographing and a round fired from the 6-inch Model 27 went high, smacking a quail right on it's narrow welded base, nearly tearing it off the target frame. It has already been mended.

So ends the .38 Special test epic. It only lacked two days taking a year to accomplish the handload testing goals. There are always more factory loads to try and I still have to get some of that pesky W231 so I'll be testing .38 Special some more in future. I don't see any other interesting propellent powders to try when testing really heavy handloads in the .38 Special so will probably not venture into that phase again.

I was hoping to shoot off a couple of the F A '26 .45 ACP cartridges I recently picked up, being able to say that they still gave a good performance over the chronograph screens after all these years, but several tries on two of the three were a bust. They were duds. I saved the best looking one for the collection.

![Image]()

This particular effort centered around handloading the .38 Special for performance using older yet recognized published data. Do not anticipate the same results by using the same loads in your own revolvers. Carefully work up to any load. Take any handloading information found on internet forums with a grain of salt.

This means you!

Smith & Wesson Model 10 2-inch

Smith & Wesson Model 10 Heavy Barrel 4-inch

Smith & Wesson Model 27 .357 Magnum 6-inch (since no 6-inch Smith & Wesson 38 Special revolver was on hand)

Smith & Wesson Model 14 8 3/8-inch

The other tests from this .38 Special epic may be accessed here:

http://www.defensivecarry.com/forum...orum/defensive-ammunition-ballistics/107972-some-38-special-velocity-tests.html

http://www.defensivecarry.com/forum/reloading/118121-three-38-special-handloads.html

The bullets tested a couple of weeks ago were from a batch I cast perhaps 20-25 years ago using the Lyman No. 358156 mould. They actually weighed 159-160 grains. They were well-formed with nice sharp shoulders and bases. They were made from straight wheel weights with some range lead thrown in as I recall (not very scientific I'll admit). They were lubed with stick Alox. I was a bit concerned that the lube would be dried out but the bullets didn't seem to lead too badly despite being abused with heavy handloads. At the conclusion of the tests the revolvers scrubbed up easily with no sterner measures required to "get the lead out."

Loads tested

The loads tested were published loads from "back in the day." Loading manuals are more mild mannered these days.

5.4 grains of Unique

This was published as maximum by Lyman for many years. A friend has nicknamed it the "Texas FBI Load" and it does make a good substitute for the factory +P 158 grain lead SWC load. The latest formulation of Unique was used for the tests. Unique seems to be "jazzed up" a bit from that used in tests 30 years ago. I first noticed this when testing Unique earlier this year. (1980 velocity tests using 5.4 grains of Unique with the lead 158 grain bullet: 2-inch-847 fps, 4-inch-935 fps, 6-inch 1021 fps, 8 3/8-inch 1007 fps).

5.0 grains of Herco

This was prepared on a whim, just to see what it could do. 5.0 grains seems to be around maximum in most data sources though the infamous Speer No. 8 shows a maximum of 6.5 grains of Herco. It was decided not to take Herco that high.

11.5 grains of 2400

This also was a published maximum by Lyman for many years. Some folks considered this to be a .38-44 equivalent handload for the .38 Special. The latest formulation of 2400 was used. I'd tested this load many years ago but the data didn't get recorded for some reason so a retest was needed. I was curious about the performance level of 2400 with the 158 grain lead SWC in the .38 Special.

8.0 grains of SR 4756

"The Load" It's bigger! it's better! It'll give all the performance one can squeeze out of the .38 Special. This is the starting load for this powder as published in the Speer No. 8 guide. I'd hate to try to work this one up to the maximum listed charge weight which is only one grain higher. Whether it is advisable to use even the listed starting load is subject to debate. Probably not. The Speer No. 8 was compiled in the late 1960s. Maybe they were smoking "cigarettes and all kinds of things" while working up loads in their lab back then.

Since we'd already tested 5.1 grains of Unique earlier this year we didn't bother to work up to maximum with it. With the other loads the effort was made to work from arbitrary lower levels in .2 grain increments toward the goal charge weights. Herco was worked up from 4.6 grains. 2400 was worked up from 10.5 grains and SR 4756 was worked up from 7.5 grains.

Working up the three loads in three different .38 Special revolvers was a bit tedious and, frankly I'm not certain that much may be determined by doing this in the .38 Special given its normal operating pressure levels. I wonder if any of the assumed pressure "signs" can be reached until one is operating fully within .357 Magnum territory which is far beyond .38 Special levels. Only the SR 4756 load showed a dab of cratering and that was in my old favorite 4-inch Model 10. Cases for all 4 loads gave normal ejection in all revolvers. Of course both "The Load" and the max. 2400 load could be straying closer to .357 Magnum pressure levels.

Some limited range time was spent shooting these loads at paper to see what sort of accuracy may be expected of them. I'm thinking that the .38 Special revolvers were grateful to see the backside of these tests.

158 Grain Lead SWC/5.4 Grains of Unique

2-inch Barrel

MV 964 fps

ME 326 ft./lbs

ES 75 fps

SD 33 fps

4-inch Barrel

MV 1026 fps

ME 369 ft/lbs.

ES 31 fps

SD 13.4 fps

6-inch Barrel

MV 1047 fps

ME 385 ft./lbs.

ES 43 fps

SD 16.6 fps

8 3/8-inch Barrel

MV 1149 fps

ME 463 ft./lbs.

ES 56 fps

SD 23.3 fps

158 Grain Lead SWC/5.0 Grains Herco

2-inch Barrel

MV 912 fps

ME 292 ft./lbs.

ES 38 fps

SD 14.3 fps

4-inch Barrel

MV 964 fps

ME 326 ft./lbs.

ES 34 fps

SD 14.5 fps

6-inch Barrel

MV 976 fps

ME 334 ft./lbs.

ES 64 fps

SD 23.7 fps

8 3/8-inch Barrel

MV 1069 fps

ME 401 ft./lbs.

ES 83 fps

SD 33.1 fps

158 Grain Lead SWC/11.5 Grains 2400

2-inch Barrel

MV 1037 fps

ME 377 ft./lbs.

ES 71 fps

SD 30.2 fps

4-inch Barrel

MV 1150 fps

ME 464 ft./lbs.

ES 50 fps

SD 26.8

6-inch Barrel

MV 1162 fps

ME 474 ft./lbs.

ES 58 fps

SD 22.2 fps

8 3/8-inch Barrel

MV 1102 fps

ME 426 ft./lbs.

ES 67 fps

SD 24.0 fps

158 Grain Lead SWC/8.0 Grains SR 4756

2-inch Barrel

MV 1150 fps

ME 464 ft./lbs.

ES 51 fps

SD 26.5 fps

4-inch Barrel

MV 1234 fps

ME 534 ft./lbs.

ES 23 fps

SD 12.3

6-inch Barrel

MV 1251 fps

ME 549 ft./lbs.

ES 23 fps

SD 8.9 fps

8 3/8-inch Barrel

MV 1173 fps

ME 483 ft./lbs.

ES 18 fps

SD 7.7 fps

It will be noted that the slower powders still register the highest velocities in the short barrel.

During this test it was surprising to find that both 2400 and SR 4756 gave higher velocities when fired out of the 4-inch and the 6-inch barrels rather than when fired out of the 8 3/8-inch barrel. This has never occurred before and I can't explain it.

It appears that the 2400 load can duplicate the performance of the Buffalo Bore +P 158 grain lead SWC factory load and that "The Load" can whip the Buffalo Bore factory load except in the 8 3/8-inch barrel of the Model 14. Buffalo Bore was the velocity champion in that barrel with the 158 grain bullet weight, strange as it may seem.

How stressful these handloads are compared to the Buffalo Bore load is hard to say. All are probably high pressure with "The Load" likely winning the prize. No primers pierced or flowed and a hint of cratering was only observed on a few, but not all of the primers in the Model 10 Heavy Barrel when used with "The Load." All cases dribbled out of cylinders when started with the ejector rod.

Recoil was brisk but very manageable in the two Model 10s. In the Model 27 and the long-barreled Model 14 recoil doesn't amount to much. All gave a snappy report and "The Load" seemed to give a particularly evil crack. Perhaps it's all in my head though.

"The Load" damaged one my spinning quail discs. I was using the top of a disc for an aiming reference for chronographing and a round fired from the 6-inch Model 27 went high, smacking a quail right on it's narrow welded base, nearly tearing it off the target frame. It has already been mended.

So ends the .38 Special test epic. It only lacked two days taking a year to accomplish the handload testing goals. There are always more factory loads to try and I still have to get some of that pesky W231 so I'll be testing .38 Special some more in future. I don't see any other interesting propellent powders to try when testing really heavy handloads in the .38 Special so will probably not venture into that phase again.

I was hoping to shoot off a couple of the F A '26 .45 ACP cartridges I recently picked up, being able to say that they still gave a good performance over the chronograph screens after all these years, but several tries on two of the three were a bust. They were duds. I saved the best looking one for the collection.

This particular effort centered around handloading the .38 Special for performance using older yet recognized published data. Do not anticipate the same results by using the same loads in your own revolvers. Carefully work up to any load. Take any handloading information found on internet forums with a grain of salt.

This means you!