Part 3 – The Barrel and Gas System

The barrel has been accurately called the heart of the AR-15. It’s the single most expensive component of the rifle itself and is the part that directly influences the bullet as you send it downrange. It's sole function is to provide a reliable path through which the fired bullet will travel, but it will also be the most determining factor in how maneuverable a rifle is. Unfortunately, it is also the subject of more voodoo than any other part of the platform; this is discussed in some detail by Kino L. Davis

here, from whom I'll be quoting much.

Currently, the list of characteristics to look for in a fighting barrel is something like this:

- Barrel length

- Gas system

- Barrel steel, construction, and rifling

- Barrel contour or profile

- Rate of twist

- chamber

Each of these will be discussed in detail.

Barrel Length

The overall length of your barrel determines both your maximum effective range and your overall weapon maneuverability. The longer a bullet can ride those expanding gases, the more velocity it will have. The longer the barrel, though, the less wieldly the rifle will be.

Maximum effective range is highly dependent on

velocity, or how fast the bullet is going when it hits something, which in turn is dependent on barrel length. Different bullets have different speeds they need to be at when hitting a target for optimal effect; M193 and M855 both require nominal velocities of 2700 feet per second (fps) to upset reliably, where the OTM Sierra bullets in the Mk262 only need to be moving 2300 fps to achieve reliable upset. Nowadays, most bullet manufacturers are nice enough to publish how fast their rounds need to be going to achieve optimal effect.

In a 20" barrel, that 2700fps mark can be achieved out to 130 yards for M193, 120 yards for M855, and 210 yards for Mk262. Drop down to a 16" barrel, and those distances become 105, 90, and 170 yards. Shave another inch and a half to use a 14.5" barrel, and that range shrinks to 105, 105, and 145 yards. This trend continues as the barrel shortens, getting harder to achieve those optimal velocities the further you go into SBR length barrels. Fortunately, we won't be using M193 and M855 for personal defense. There are much,

much better options. Barnes TSX bullets, for example, work well down to 1800 fps. The specialty Hornady and Sierra bullets, while not quite as effecient, still do well at much slower speeds than the 2700 required by the M193 and M855. With most modern self-defense rounds, we can still have 100+ yard capability from our rifles even out of short, NFA-length barrels.

While the most likely scenario of us using an AR-15 for personal defense is within the home, we shouldn't ignore the long shots either. Look down your street and guess about how far your house is to the nearest stop sign, or how far your back yard extends beyond your house. Try the same exercise in a parking lot, estimating from your car to a couple random other points. Civilians and law enforcement alike can very easily be pressed into 25-100 yard shots, which makes those needed feet per second somewhat more important than they would be if the weapon would only be used in bad breath range.

For most of us, a 16" or 14.5" barrel with a permanent muzzle device will be the best compromise. The 16" barrel gives a little more flexibility and lets you choose different muzzle devices, but costs you another 1.5" of overall length. Both of them spare you the headache of NFA paperwork. If you're willing to go through the process, though, an 11.5-12.5" barreled gun is probably the ideal length for maneuvering inside a home, with modern ammunition letting that SBR be effective even out to/past 100 yards.

Gas System (warning - long read)

Before going into this, we need to look at how the AR-15 actually works. This is good to know in general, great to know when fixing a factory gun, and should be considered mandatory to know for building your own.

When a round is fired, an immediate pressure spike builds inside the cartridge case. The cartridge expands outward, contained by the chamber and bolt face, which hold the case in place and forces the propellant to push as the bullet is propelled down the barrel. The bullet is moving a lot faster than the bolt face due to its smaller mass, so the propellant gases expand down the barrel and push the bullet ahead of them. Remember that the gas port is a hole in the barrel designed to siphon off some of those expanding gases to cycle the action. Once the bullet passes the gas port, some of of the pressure is lost. The total pressure built up until this point is the

chamber pressure, and will drop dramatically (to 12-15k PSI or so) until the bullet passes the muzzle. The moment the bullet leaves the barrel, gasses escape behind the bullet going several times faster than the bullet itself.

During that time between the bullet passing the gas port and it leaving the barrel, a specific amount of gas was expanded into the gas port, down the gas tube, and into push the the gas piston on top of the bolt carrier. Here it will expand into that little chamber just behind the bolt. In doing so, it forces the bolt forward

and the bolt carrier backward. The pressures that originally pushed

back against the bolt are more or less equal (for a short time) with the pressure of the gas now behind the bolt. By now the cartridge case should have returned to its original size and the bolt will begin to turn and unlock, followed by the extractor pulling back on the case head. The rearward force against the bolt carrier group eventually overcomes the forward force on the bolt, causing it to move backwards against the inertia of the carrier's own weight, the buffer's weight, and the action spring.

The whole time the case head is held by the bolt, the ejector has been putting pressure on one side of the case head. Because it's been held in place by the chamber, it hasn't gone anywhere. Once the bolt carrier group moves far enough back to pull the spent casing from the chamber and to the ejector port, the case no longer has counter-pressure on its right side and the ejector kicks the spent casing out.

To quote

Randall from AR15barels.com,

We want the bullet to be out of the front of the barrel AND the pressure to have subsided enough that the case shrinks down BEFORE the bolt lugs are unlocked because when the pressure is high, the case WILL try to stay in the chamber.

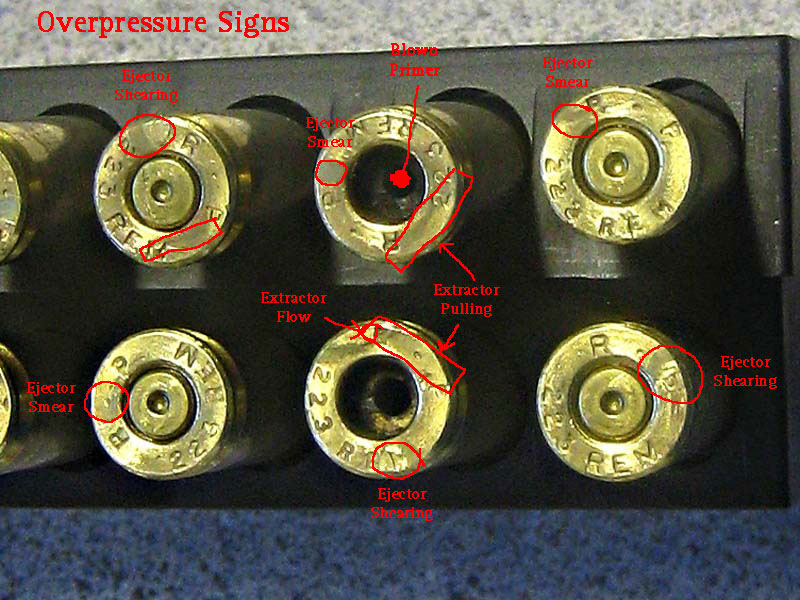

Now is the perfect time to point out that one sure sign of high pressures are the fact that the case extrudes into the ejector plunger hole on the bolt and the resulting pressure unlocks the bolt while pressures are still high.

This extruded brass gets wiped off the end of the case head, leaving a shiney spot and the brass usually makes it's way under the extractor, later causing extraction problems we will get to in a little bit.

Here is a graphic illustrating what happens when pressures are too high and the gas system is getting too much gas:

Most of what I described is also described in as much, or more, detail on Randall's site. As you can see, this whole process is

highly dependent on timing, hence the different weight buffers that exist to regulate said timing.

Now we can talk about the actual gas systems used in the AR family of weapons.

The rifle length system, a 20" barrel with the gas port located 13.2" out, is the original gas system for the M16. Adopting shorter barrels necessitated the Carbine system, with the port 7.8" out on what was originally a 10-11" barrel, then evolved into the standard 14.5" barrel we see on M4s today. The mid-length system, with its gas port 9.8" out, was developed much later primarily for 16-18" barrels.

When we talk about the 'gas system' of a barrel, we're talking about gas port location, specifically the distance from the breach to the gas block. If you remember, chamber pressure is the total pressure exerted on the bolt and chamber in that time between the round being fired and the bullet clearing the gas port. Different gas systems result in different pressures.

As you can see, the further out the gas port is, the lower the chamber pressure. Think about it like an explosion in a room. The smaller the room, the more the pressure builds before being allowed to expand. The larger the room, the more the gases can expand before the pressure builds. For the same reasons, chamber pressures are lower on the longer gas systems of the mid-length, intermediate (not listed), and rifle systems. This leads to fewer pressure related failures - blown primers and ruptured cartridges are prime examples.

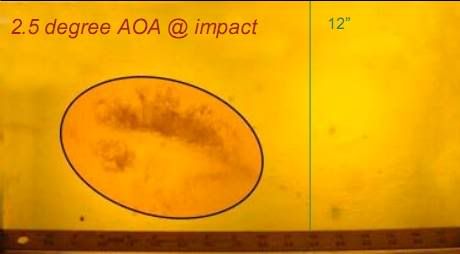

Now that the bullet has passed the gas port, we get to another critical point: that time between the pressure bleed off at the gas port, and when the bullet ultimately leaves the barrel. In the gas operated system of the AR-15, we call this dwell time.

Dwell time is basically the amount of time that the bullet is past the gas port, but still in the barrel. It's a simple enough concept, but a critical one to know if you want to understand how an AR-15 works. Until that bullet passes the gas port, the AR is a single-shot rifle; the bullet

must clear the gas port to allow those expanding propellants to expand into the gas port, down the gas tube, and into the gas piston on the bolt carrier. However, without the bullet blocking gas expansion down the barrel, the propellants would simply expand out the barrel instead of up into the gas port. The bullet acts as resistance to the expanding gases, forcing them to enter the gas port and operate the rifle's action while waiting for the bullet to leave the muzzle so the gases can expand out behind it.

If dwell time is

too long (a longer distance between gas port and muzzle), more gas enters the gas port and the carrier group is pushed back more harshly than is necessary. This is called overgassing, which will wear down parts quicker and produce more felt recoil in the form of a harsher recoil impulse (the actual amount of recoil doesn't change, just how it feels). It can also disrupt the timing of the bolt carrier, causing malfunctions in extraction or ejection*. If the dwell time is

too short (shorter distance between gas port and muzzle), not enough gas enters the gas port and the carrier group may not be pushed back far enough to cycle the action or lock back on the last round. This is undergassing, or more commonly known as short-stroking. It's gentler on the rifle and has a softer or smoother recoil impulse, but basically gives you a single-shot rifle. What we're looking for is that 'golden mean', that sweet spot in dwell time so that our rifle is fed enough gas to function reliably but not so much that it is worn down prematurely or that the recoil becomes harsh.

It just so happens that a few folks have done just that kind of research. Credit again goes to Randall.

Advice time.

Most people* using a 16" barrel will be best served by a

mid-length gas system.

Most people using a 14.5" barrel will be best served by a

carbine gas system.

If buying a short-barrel rifle, buy quality from the get-go:

Bravo Company,

Centurion Arms,

Colt carbines modified by Specialized Armament,

Daniel Defense,

Lewis Machine & Tool, and

Noveske Rifleworks. Conveniently enough, those are basically our go-to companies for most parts AR-15 related**.

*I say "most people" because most people will not be mucking about with the guts of their rifles after buying or putting them together. There is a growing trend in using 14.5" mid-length barrel systems. Everything else being equal, they

do feel differently than 14.5" carbine systems. Combined with a heavier buffer and/or modified buffer system like Vltor's A5, it is possible to create an

extremely low-recoil system. Bushmaster popularized the "Dissipator", visually resembling a 16" barrel with a rifle gas system and handguards. In reality it is a carbine gas system hidden under the handguards, but the attraction of a larger grip surface, lower chamber pressures, and softer recoil has resulted in some folks toying with the gas port size to account for the abnormal dwell time. When the system works, it is awesome how smooth the weapon feels while still keeping a shorter 16" barrel. Getting it to work takes effort, though.

** Many companies (Bushmaster, DPMS, RRA, S&W, etc.) intentionally overgas their systems by using larger-than-normal gas ports. It lets them function on weaker ammo, but makes the stronger ammo harsher on the rifle and more prone to inducing damage or malfunctions. The simplist fix for this is using different weight buffers. Companies like Bravo Co., Daniel Defense, Noveske, and others do not have access to the TDP like Colt, but instead conduct cyclic rate testing to fine-tune their gas port sizes.

Barrel Steel, Construction, and Rifling

Barrel Steel

Do you know the differences between chrome-moly 4140, 4150, and CMV? What about 410, 416, and 17-PH stainless? If you read my previous link to the

M4C article by Kino Davis, you'll be ahead of the curve. If not, don't worry, I'll be quoting him a bit. Starting now, in fact.

About 99% of barrels are made up of one a few different types of steel alloy -- of these, the choice is pretty much between Chrome-Moly steel and Stainless Steel.

Chrome-Moly - This name is used to describe a broad family of steels, the most common in use for the AR are 4140 and 4150... the 41xx indicates the AISI-SAE numbering for Chromium-Molybdenum alloy (ergo the name Chrome-Moly), these steels are alloyed with about 0.50% to 0.95% Chromium and 0.12% to 0.30% Molybdenum. The second part of the number indicates that percentage of Carbon (in tenths of a percent). Therefor 4140 is about 0.40% Carbon and 4150 about 0.50% -- the extra carbon in 4150 makes the steel a little tougher and it resists heat better... but it is harder to work and machine.

4150 is one of the "MilSpec" steels... another that is used in a lot of military barrels is CMV (Chrome-Moly-Vanadium) -- as the name implies, this is a chrome-moly steel (very close to 4150) with the addition of about 0.20% to 0.30% of Vanadium. CMV is reported to perform better under high heat.

Carbon steel barrels (chrome-moly) are the bread and butter of barrel materials for the AR, chrome-moly has made great barrels for many years and will continue to do so for many more. The only real downside to carbon steels is that they are prone to rust and corrosion problems.

Stainless Steels - We all know stainless steel, very high levels of chromium and nickel make these steels very resisitant to rust and corrosion, they are used in nearly every type of manufacturing around... the most common choices of stainless for a barrel are 410 and 416. There are a few "families" of stainless steel, but all of that is really academic to the discussion -- but 410 and 416 are Martensitic steels... simply they have lower percentages of chromium than other types of stainless steel.

The most common stainless in use for AR barrels is 416, this steel is plentiful, not expensive and machines nearly as well as the carbon steels -- 416 is rather strong, and has decent corrosion resistance; however, it is one of the least corrosion resistant of the stainless steels. Another choice barrel makers offer is 410, it is a little tougher and more corrosion resistant, but is harder to machine.

Grade 630 stainless, often called 17-4PH, is a great steel that offers excellent corrosion resistance and hardness. 630 is tough, but machinable, and tempers well. It is a precipitation hardened (PH) or age hardened steel and does not distort significantly during the hardening process; however, one consideration for the use of 630 is that the steel manufacturers do not recommend using it for applications that will expose it to cycling temperatures above 700 (f) -- In some cases this is not an issue, however in an AR that may see "heavy fire", 630 (17-4PH) is not a great choice.

So which is better, CM or SS? Again, this depends on what you want/need... a few things that seem to hold true about the two are that: CM barrels may take a little longer to break in and can be more prone to copper fouling; Due to the way the metal erodes in the throat area, the acuracy of CM barrels tends to degrade at a more steady rate, where SS tends to fall off quickly towards the end of its life; The throat area of CM barrels can work harden, this makes recutting the chamber and "bumping" the barrel back difficult -- but AR barrels can not be bumped back anyway (due to the gas port); SS barrels tend to be more prone to scratching but naturally is better at resisting corrosion (over an unplated CM bore); Many barrel manufacturers do not recommend using SS in sub-zero cold; Either SS or CM is capable of the same accuracy and will have about the same service life.

Generally speaking, barrels described as Mil-B-11595E chrome-moly vanadium steel are what we want. These should also come with chrome-lined bores and chambers for better corrosion resistance; I don't believe I've ever seen a Mil-B-11595E CMV barrel that was unlined.

Construction and Rifling

Once the barrel blank is made, it gets rifled before being profiled. There are several ways of accomplishing this - button rifling, broach cutting, single point cutting, hammer forging, checmical or anode/cathode etching, etc. For AR barrels, we really only care about two: button rifling and hammer forging.

The vast majority of AR barrels are rifle buttoned. This involves pushing or pulling a rifled button through a barrel blank and forcing the rifling into the bore. There is nothing inherently wrong about the technique; it is how Colt and FN Herstal make the M4 and M16 series weapons for our own military. As long as you're buying from a good source (like one of the manufacturers listed earlier), you can enjoy a long, happy lifespan on your rifle-buttoned barrel.

With this in mind, a number of companies have brought to market cold hammer-forged barrels. CHF barrels are generally much more durable and have significantly longer service lives, at the cost of being slightly to not-so-slightly more expensive than non hammer-forged barrels (in some cases commanding a $100 or higher premium). Excepting LMT, all of the previously-listed companies make CHF barrels; excepting Colt's, all are available commercially. I don't believe it's possible to get a Colt hammer-forged barrel - to my knowledge they're made exclusively for the C7s and C8s in use by our northern brothers.

The type of rifling is another much-debated point that we really, honestly, truly don't need to worry about. Buy a barrel from one of the aforementioned manufacturers and you will be just fine. Type of rifling comes into play more for competition shooters going for extreme accuracy, often at long distances. Even in defending one's rural property it would be hard to find a home-defense scenario in which the type of rifling your barrel has will make or break your abiltiy to defend yourself or your loved ones.

Barrel Contours

Heavy rifles suck. They're slower to move around and they tire you out quicker. Given that your barrel is a long tube of steel, its profile (the external diameter and how it changes along its length) will play a pretty significant role in determing the overall weight and balance of your rifle. Case in point:

Colt 16" HBAR: 2 pounds 3.4 ounces

Colt 16" M4 profile barrel: 1 pound 12 ounces

Colt 16" lightweight profile: 1 pound 6 ounces

There are many different types of barrel contours, ranging from heavy barrel (HBAR) profiles an inch or more in diameter to lightweight and pencil barrels nearing half-that. Of the many different profiles, the government profile is the most common: thinner under the handguards, thicker past the gas block. Not because it's better than others (quite the contrary, in fact), but simply because it's what is on the M4 and M16 series carbines and rifles. Adding another 6 ounces or more to the

end of the barrel is not an exercise in brilliance.

Generally speaking, the thicker the barrel is, the more it resists changes in temperature (takes longer to heat up and cool down) and the less it will flex when fired. Thinner barrels are just the opposite, less resistant to temperature changes (heating up quicker and cooling off quicker) and more prone to flexing when fired. Flex matters a lot in accuracy shooting, and matters more the further out you get. This is when barrel heat also matters; the hotter a barrel gets, the more point of impact will shift. Inside of 100m, though, it would be very difficult to argue the point. In home-defense scenarios, it's equally hard to imagine shooting enough quickly enough to heat the barrel such that temperature resistance matters.

Manueverability is directly influenced by barrel weight

and where that weight is distributed. A 1 pound 12 ounce Noveske contoured barrel will handle much differently than a 1 pound 12 ounce M4 profile barrel simply because of where the weight is. Keep in mind that physics is pretty consistent: it doesn't matter how big or strong you are, you will always move a lighter rifle quicker than a heavier rifle. Similarly, on equivalent weight barrels, the one with the most material closest to the receiver will also be the quickest.

Opinion: It's for this reason that I greatly prefer lightweight barrels - speed counts when a door is kicked in or window broken through and a lighter, better balanced rifle is always

more maneuverable than a heavier rifle with poorer balance. While there is a lot of hemming and hawing about the sacrifices made when choosing anything short of a bull-barrel, even the less-than-optimally designed M4 profile survived more than 500 rounds of full automatic fire before rupture. That's 16 or more 30-round magazines, as fast as the gunner can feed them, without lube (courtesy of NY Times and .mil.) Even if the lighter weight barrels do fail sooner, it is nearly inconceivable to require the dozen or more magazines worth of full-auto fire to protect my home and family necessary to push the barrel to failure.

Rate of Twist

This ratio describes the length the bullet will travel to complete one full rotation within the barrel (ex: A 1:7 barrel means the bullet travels 7" to make 1 full rotation). The original twist for the M16 was 1:14, which combined with the 55 grain M193 produced outstanding terminal effects but poor penetration and poor accuracy in cold weather. Tightening up to 1:12 vastly improved its external ballistics at the cost of its terminal ballistics (we'll go into ballistics in a later section). In the M16A2, the barrel twist tightened all the way to 1:7 to properly spin the longer tracer rounds.

Without delving too deep, we care much more about 1:7 and 1:8 twist barrels than any others. As described by this article on PoliceOne, the biggest consumer of all small arms ammunition is the military, meaning ammunition manufacturers have been catering to the 1:7 twist for .224 bullets for a long time and have developed some great rounds for personal defense... for the 1:7. Using the excellent Sierra 77gr OTMs, Hornady 75gr T2, and several other heavier/longer bullets, the 1:9 twist barrels are inconsistent. Some of this falls on the manufacturer (RRA's 1:9 vs DPMS's 1:9); according to Giles Stock, some 1:9 barrels will run closer to 1:8 and do well with the heavier/longer ammo while some will run closer to 1:10 and do miserably with it. 1:12 twist barrels need not apply - there military specifically moved away from the 1:12 twist because it could not handle the longer bullets in the XM856 phospherous tracers. Though looser twists can't [usually] handle longer bullets, 1:7 and 1:8 twist barrels have little or no trouble shooting lighter/shorter .224 bullets.

Technically, the 1:8 twist barrel is perfect for anything that will fit in an M16 30-round magazine. It's just harder to find because 1:7 is used by the military and works so well in general. For our purposes, the 1:7 and 1:8 are what we want in an AR barrel, with availability favoring the 1:7.

There is some decent ammunition for 1:9 and 1:12 twist barrels, but your options are greatly reduced. Ammunition will be discussed in greater detail later.

Chamber

This should be a very short section: 5.56x45 NATO is the only chamber we really care about as consumers buying a rifle for personal defense. Noveske uses a modified 5.56 chamber similar to the .223 Wylde in their stainless barrels that is also fine (and well it should be, since it's designed for full-auto fire of Mk262).

The problem with just leaving this recommendation at the previous two sentences is that many companies flat lie. What's printed on their barrels and receivers is very often not the actual chambering of the weapon: 5.56 is just as often .223 Remington. Bushmaster, DPMS, Olympic Arms, Rock River Arms, and Smith & Wesson are all guilty of this in the past and present. This is not a small deal - there is about a 20,000 psi difference between NATO and SAAMI specs for chamber pressure. The .223 Wylde chamber, a hybrid of 5.56 NATO and .223 Remington and seen most often in RRA rifles and LaRue rifles, can be fine. In theory. It has far fewer reported issues when running 5.56 ammo than using the same in .223 Remington weapons. RRA may be questionable at best, but LaRue is certainly not.

A great comparison of reamers for the .223 Rem, 5.56 Nato, and various hybrids can be seen here. You can briefly summarize the differences like so:

The 5.56 chamber is a sloppy military chamber with a long throat(.226 diameter and .056 long), the .223 chamber is tighter in all dimensions and has a shorter throat(.025 long), works well with varmint bullets.

The Wylde has a generous chamber size but the throat is smaller in diameter(.224) to hold the bullet in line with the bore better , the freebore is .061 long.

(Continue to Part 4)